What are the differences between extrusion and cast acrylic sheet

Acrylic material is a common material in the second-processing industry. According to the different manufacturing processes, extrusion and cast acrylic sheets have some differences in terms of physical properties and applications.

Below we made a comparison for these two materials.

| Item | Extrusion Acrylic Sheet | Cast Acrylic Sheet |

|---|---|---|

| Production | The Extrusion Acrylic sheet is produced by PMMA resins. By melted the PMMA resins and extruded the material from T-Die to form the final sheet. | Cast acrylic is produced by mixing the acrylic liquid ingredients in molds. |

| Chemical Resistance | Less chemical resistance | Higher chemical resistance |

| Thickness Tolerance | ±5% | ±15% |

| Flame Polishing | Easier to flame polishing | More difficult to flame polishing |

| Tension | High tension | Low tension |

| Hardness | Lower hardness | Higher hardness |

| Scratch Resistant | Less scratch resistant | More scratch resistant |

| Application | stationery, billboard, furniture, fashion product | signage, display stand |

| Colors | Limited color selection | Wide color selection |

| MOQ | High MOQ per color and thickness | Accept small batches of colors and thicknesses |

| Surface covering | PE film Brown paper masking | PE film Brown paper masking / White paper masking |

| Second Processing | Heat bending | Laser engraving |

| Thermoforming | Laser cutting | |

| Bonding | Heat processing |

- Related Products

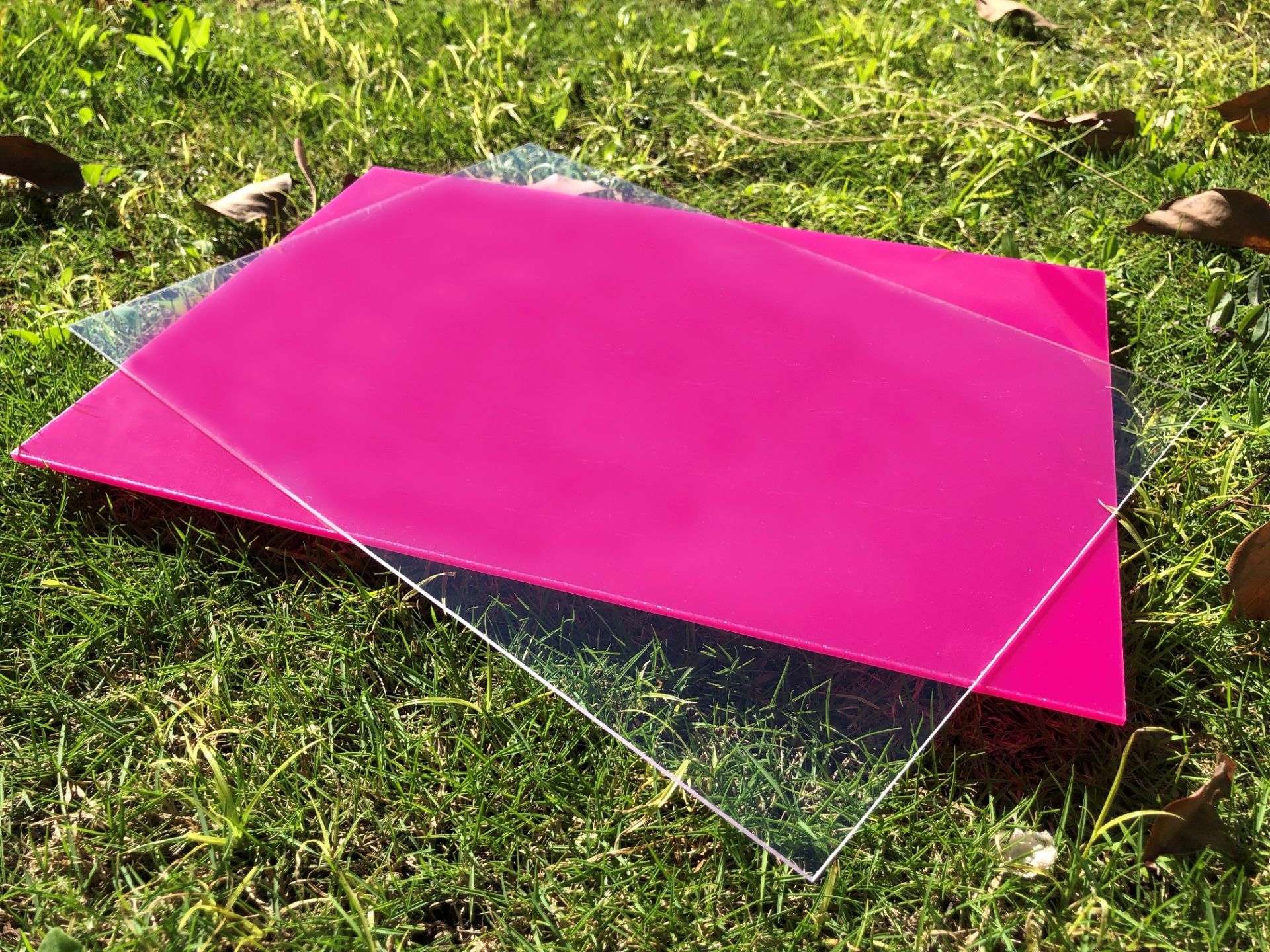

Cast Acrylic Sheet Transparent

AC000

Cast acrylic is produced by mixing the acrylic liquid ingredients in molds. For acrylic plates...

DetailsClear Acrylic Flat Sheet

AE000

Clear Acrylic Flat Sheet has a high gloss effect, excellent chemical resistance, weather resistance,...

Details